Working with the aerospace industry means bringing your A-game every single time. HDH Instruments has built a reputation on precision aerospace drilling that holds up under pressure. With half a century of hands-on experience, we know how to meet the tight specs and deliver the consistent quality aerospace manufacturers rely on.

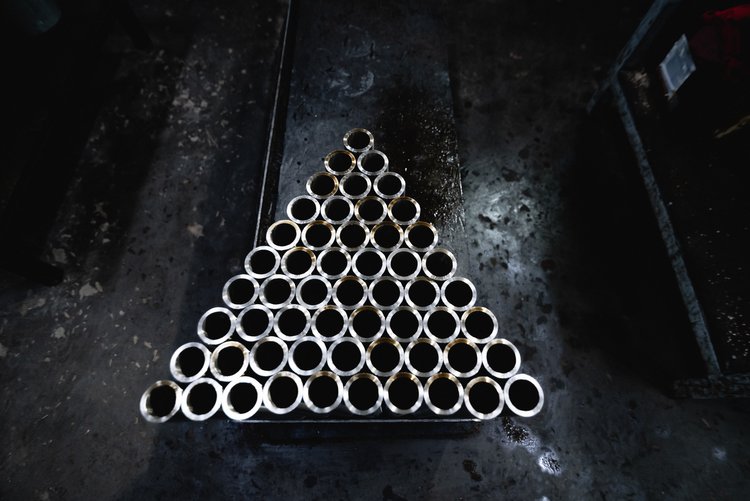

Precision Aerospace Gun Drilling

Precision matters in aerospace, and when it comes to drilling deep holes into tough materials, we know exactly what we’re doing. Our aerospace gun drilling process produces clean, accurate holes, even when working with extreme depths and complex specs.

Aerospace materials don’t leave much room for error. That’s why we’ve taken the time to learn how each alloy behaves during deep hole drilling. HDH works with the industry’s most commonly used grades, such as 6061 aluminum, 304 and 316 stainless, and 718 inconel, on a daily basis. From rugged landing gear components to the precision demands of control systems, we’ve got the tools, and the experience, to get it right every time.

Full-Scope Aerospace Gun Drilling Services

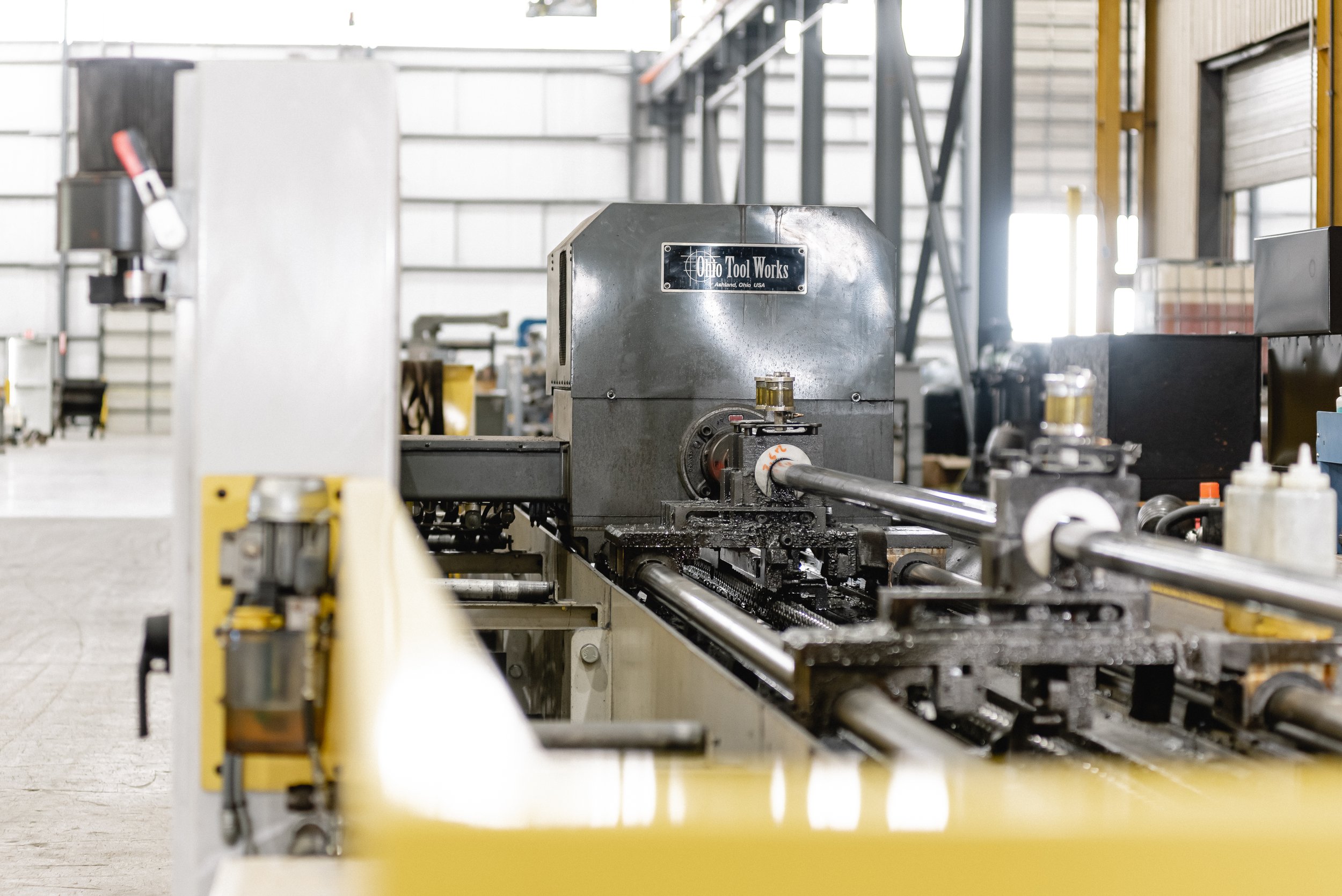

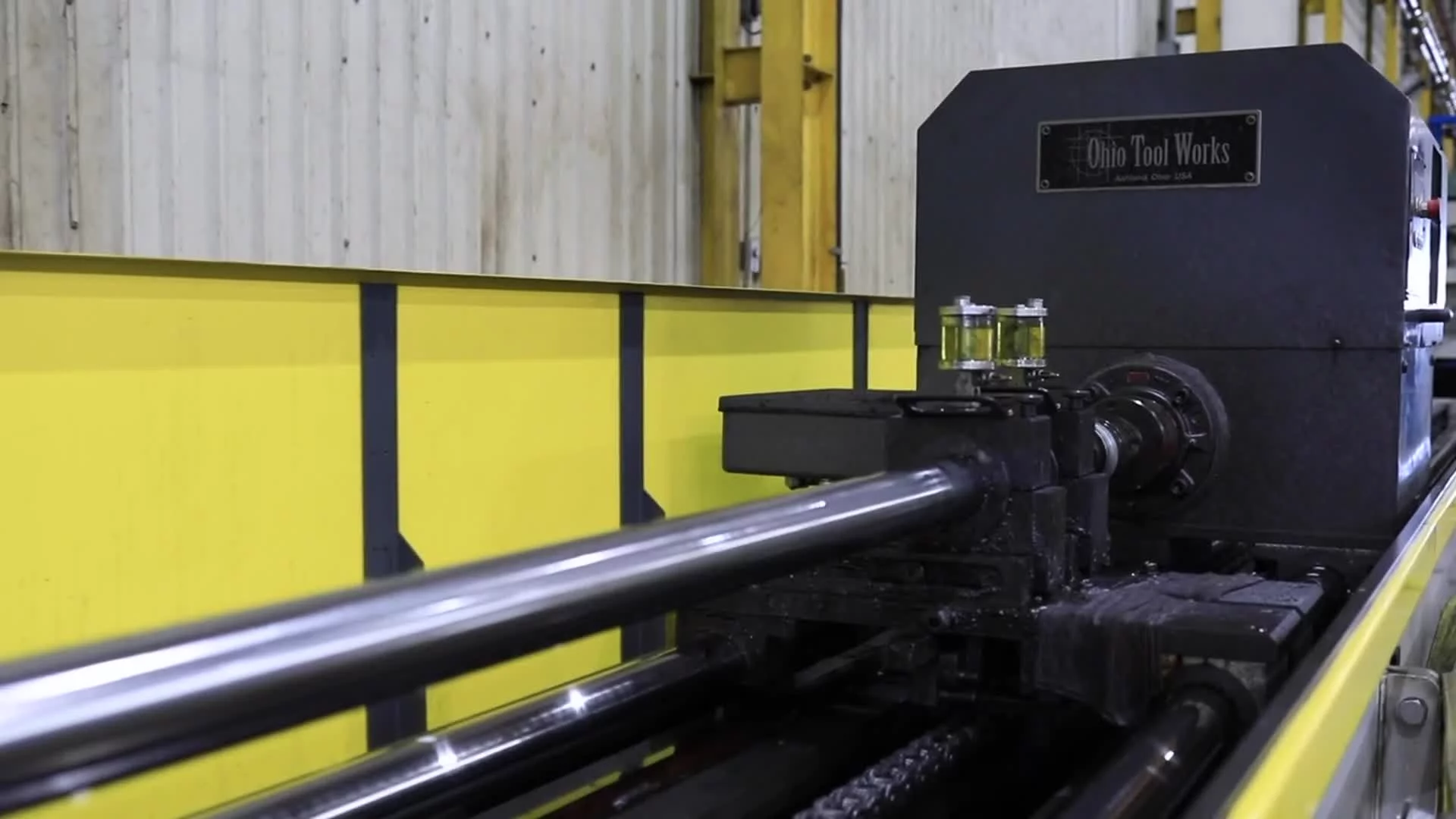

From concept to production, we offer aerospace gun drilling services that scale with your project. Need a single prototype or a full run of parts? We’ve got the capability and systems in place to deliver, on time and up to spec, every time.

We handle on-center diameters ranging from .062” up to 1.50” in lengths as long as 150” depending on hole size, as well as custom part handling for unique shapes and specs. Our team works shoulder-to-shoulder with aerospace professionals to make sure every component aligns with your engineering goals and functional requirements.

Aerospace Deep Hole Drilling Capabilities

Deep hole drilling in Aerospace isn’t easy, but we’re built for it. Our shop handles long parts and large diameters with serious precision. We can drill internal diameters from .984” up to 8.00” as well as trepan up to 14.00” reaching lengths as long as 415”, giving us one of the largest capacities available in the U.S.

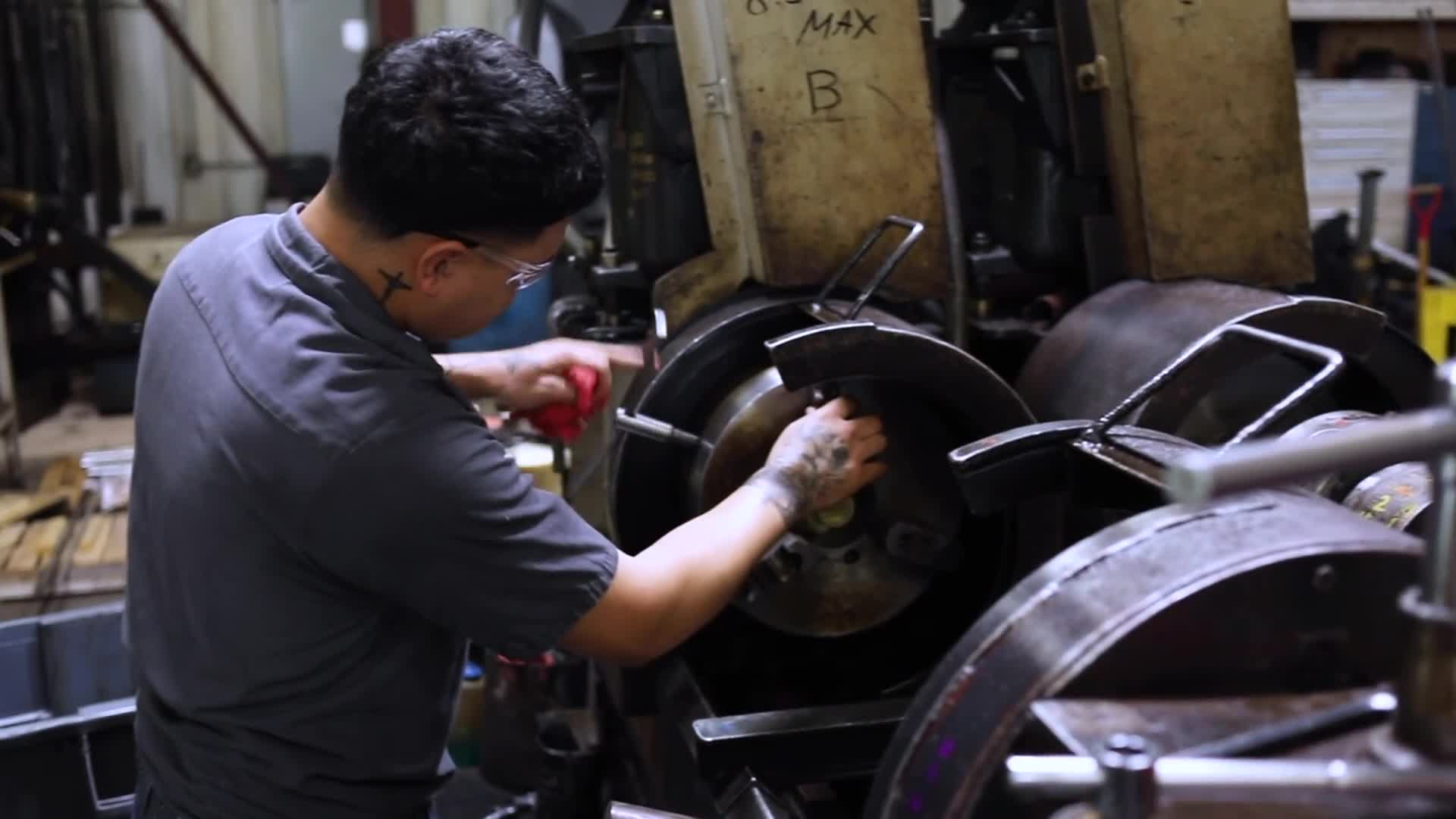

This matters when you’re machining things like long actuators, high-pressure cylinders, or other structural components that need perfectly straight, deep holes. With the right tools, skilled operators, and tight process controls, we keep everything aligned from start to finish.

Applications in the Aerospace Sector

Our aerospace drilling expertise supports a variety of components used in aircraft, satellites, defense systems, and spacecraft. Typical applications include:

- Landing Gear Components: Deep-drilled struts and shafts designed for extreme impact and load-bearing requirements.

- Hydraulic Actuation Systems: Precision channels for fluid movement in mission-critical aerospace controls.

- Turbine Engine Parts: Components designed to perform under high heat and rotational stress.

- Flight Control Assemblies: Drilled to support responsiveness, redundancy, and mechanical stability in flight.

Why Aerospace Leaders Choose HDH

HDH Instruments engineers trust. We know aerospace is a different kind of challenge, where precision isn’t a bonus, it’s a baseline. There’s no room for mistakes. That’s why our clients trust us for aerospace gun drilling and aerospace deep hole drilling that meet the tightest specs, cleanest finishes, and strictest quality expectations.

Let’s Drill Into Your Next Project

When your aerospace project needs deep hole or gun drilling, we’re here with the tools and the know-how to handle it. HDH Instruments brings proven experience and sharp attention to detail to every job.

Contact us now to start the conversation and see how we can support your build.