At HDH Instruments, we provide precise machining services to support the demanding needs of the oil and gas industry. With decades of experience, we understand the different challenges faced by companies in this sector, from deep drilling operations to equipment reliability in harsh environments. Our team specializes in a variety of services, all aimed at delivering high-quality solutions for oil and gas applications.

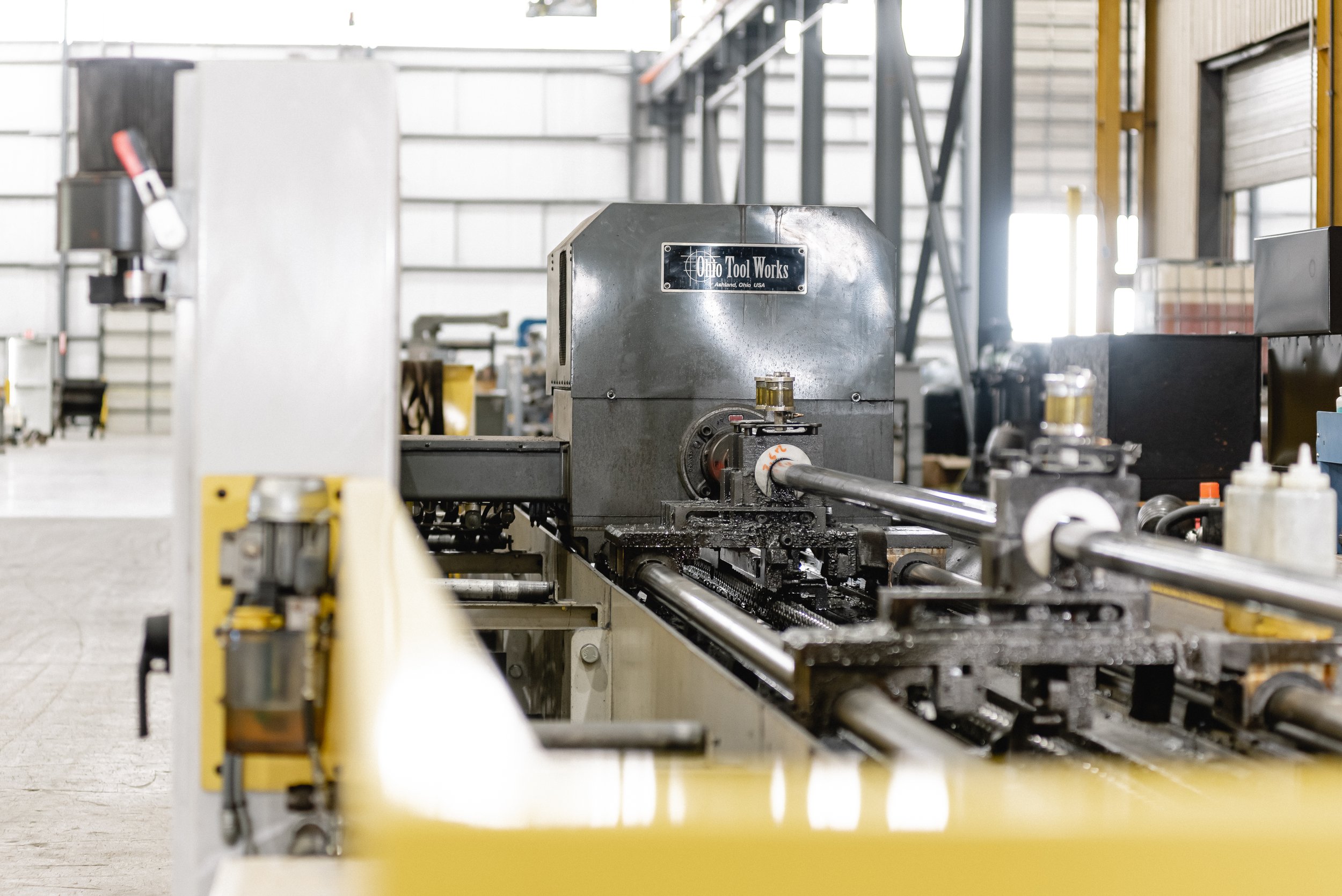

Deep Hole Drilling Services

Deep hole drilling is a critical service for the oil and gas industry, particularly for creating long, straight holes in drilling and completion equipment. Our deep hole drilling services cater to projects that require precision and durability. We are equipped to drill holes with internal diameters ranging from .984” to 8.00” and lengths exceeding 35 feet. These capabilities are essential in downhole applications, where depth and accuracy are crucial for successful extraction processes.

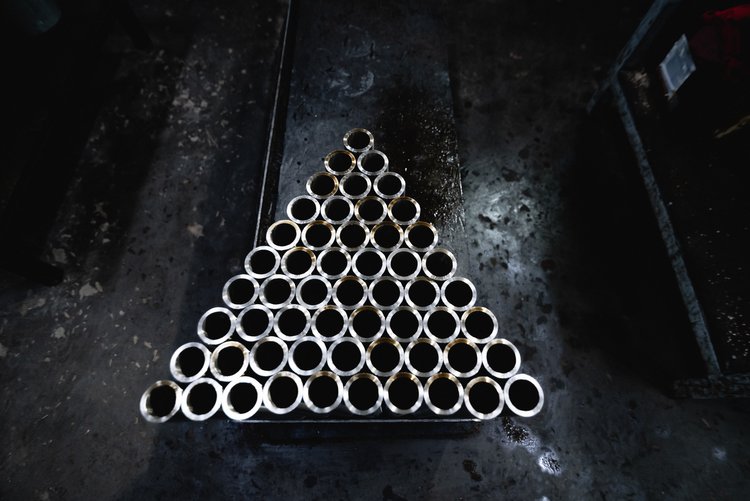

Honing Services

Honing services at HDH Instruments provide a high level of precision for refining the internal dimensions and surface finish of oil and gas equipment. Our honing capabilities are applied to various components such as PBR/TBR’s, liner hanger systems, OCTG casing & tubing conversions, and various BHA (bottom hole assembly) components , where the highest accuracy is necessary to guarantee effective performance. We specialize in achieving smooth finishes and fine tolerances, which are essential for downhole tools operating in challenging environments.

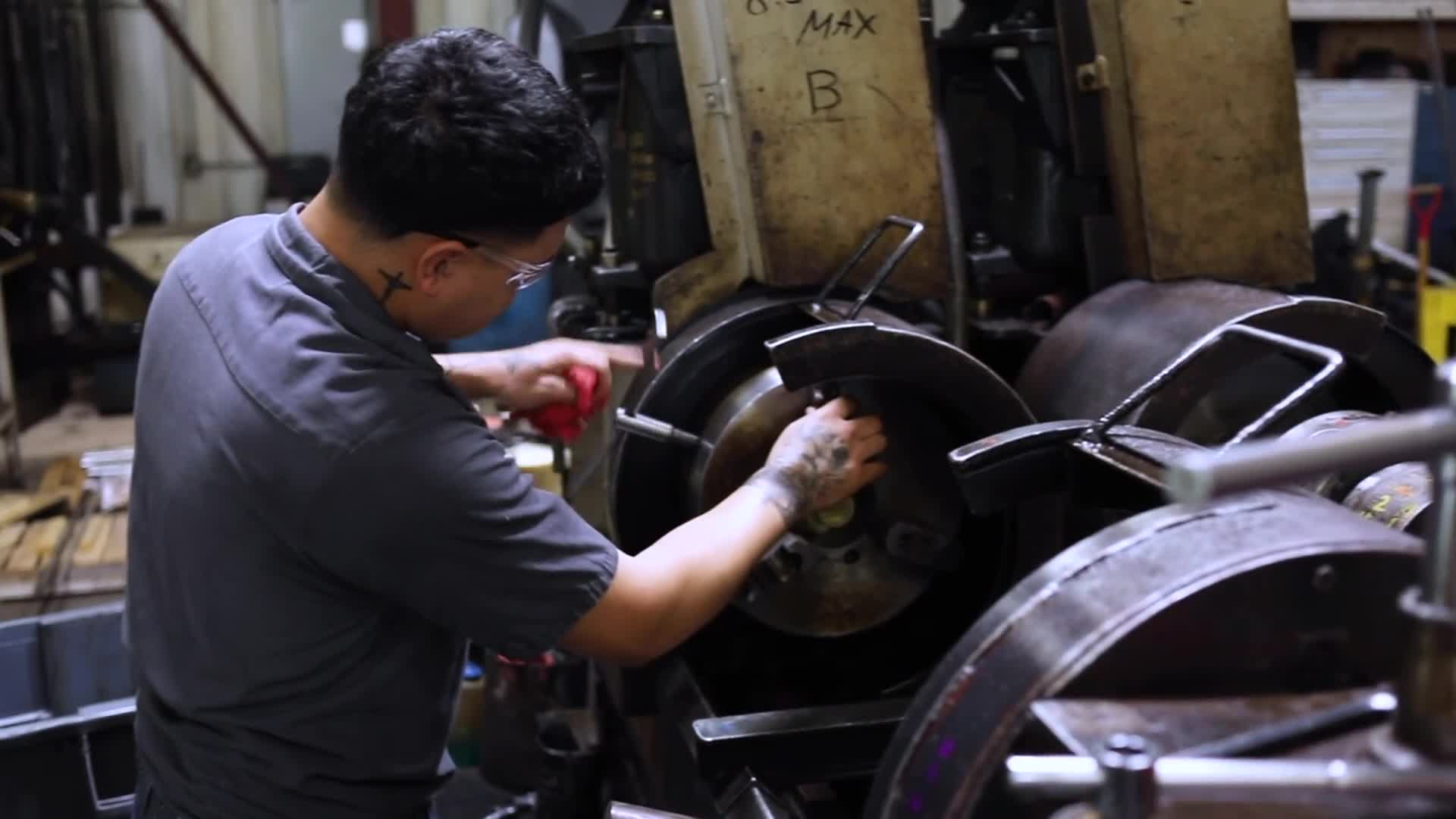

Tube Boring Services

Tube boring is another specialized service we offer, designed to maintain the integrity of cylindrical components used in oil and gas applications, while also supplying better-than-industry-standard surface finishes. With diameters ranging from 1.80” to 8.50” and lengths up to 45 feet, our tube boring services provide the accuracy needed for components like stators, blast joints, drill pipe, and OCTG casing & tubing conversions. This process is vital in ensuring the stability of drilling and completion supply chains, and our tube boring services help keep them in optimal condition.

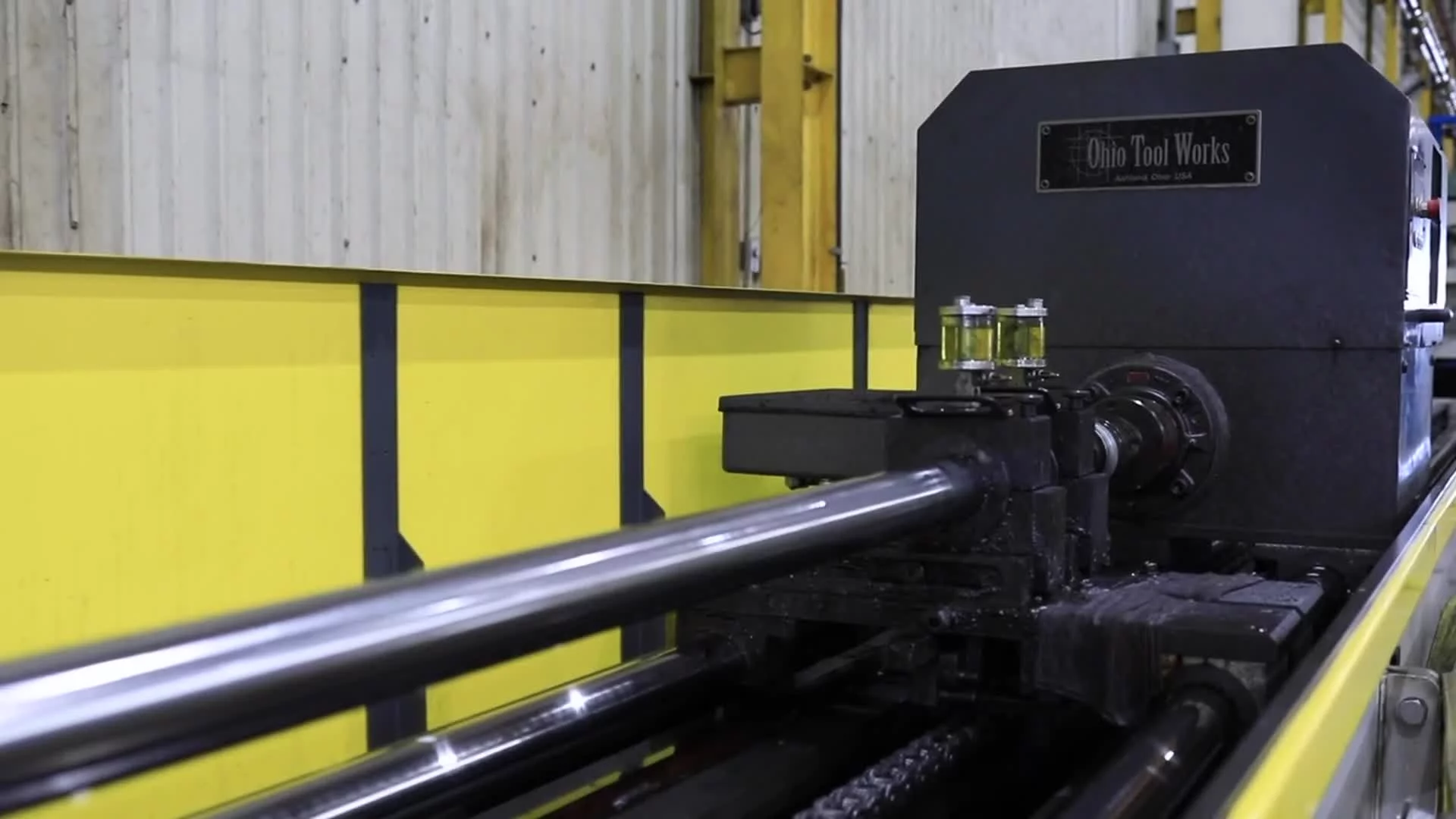

Turning Services

HDH Instruments also offers precision turning services, which are ideal for components requiring tight tolerances and stringent concentricity. Turning in the oil & gas industry is used to machine cylindrical parts of all sizes, where exact measurements are critical to ensure proper fit and function. Our turning services are made to meet the specific needs of the oil and gas industry, where precision and performance are a priority. Whether roughing out large diameter flanges or finishing a 40 ft long mandrel, HDH has over 35 lathes to fit every need.

Gun Drilling Services

Our gun drilling services are perfect for creating deep, straight holes that are often needed for oil and gas drilling operations. We specialize in small-diameter holes with high accuracy, which are essential for drilling rods, MWD / LWD tools, actuators, and other critical components.

Straightening Services

Straightening services are essential for correcting bent or deformed parts that are common in raw material prior to machining. Having the ability to straighten is just as critical to provide precision tubes once all machining is completed, with many applications requiring parts to be straight within .005”. At HDH Instruments, we have the capacity to straighten components with diameters up to 16.50” and lengths up to 45 feet. Whether it’s for OCTG, drill pipe, heavy wall hollow bar, or precision machined components, straightening services help maintain the integrity of these parts, ensuring fit and function during assembly and compliance to industry requirements.

Bottom Hole Assembly (BHA) and Downhole Tool Conversion

HDH Instruments plays a key role in the production and maintenance of Bottom Hole Assembly (BHA) tools. These assemblies are critical in the drilling process, and our machining services are a perfect fit in manufacturing many of necessary tools for optimal performance. In addition, we offer downhole tool conversion services, which involve modifying or refurbishing tools for different drilling needs or sizes. This extends the lifespan of expensive equipment, reducing downtime and improving operational efficiency.

Why Choose HDH Instruments for Oil & Gas Solutions?

HDH Instruments has built a reputation for providing precise, reliable machining services that meet the exacting standards of the oil and gas industry. We work closely with our clients to provide solutions that enhance the efficiency and durability of their equipment, making sure that operations run smoothly and safely.

For oil and gas companies looking for reliable machining services, HDH Instruments offers the experience, expertise, and equipment needed to meet every challenge. Contact us today to learn more about how we can support your operations with our high-precision machining services.