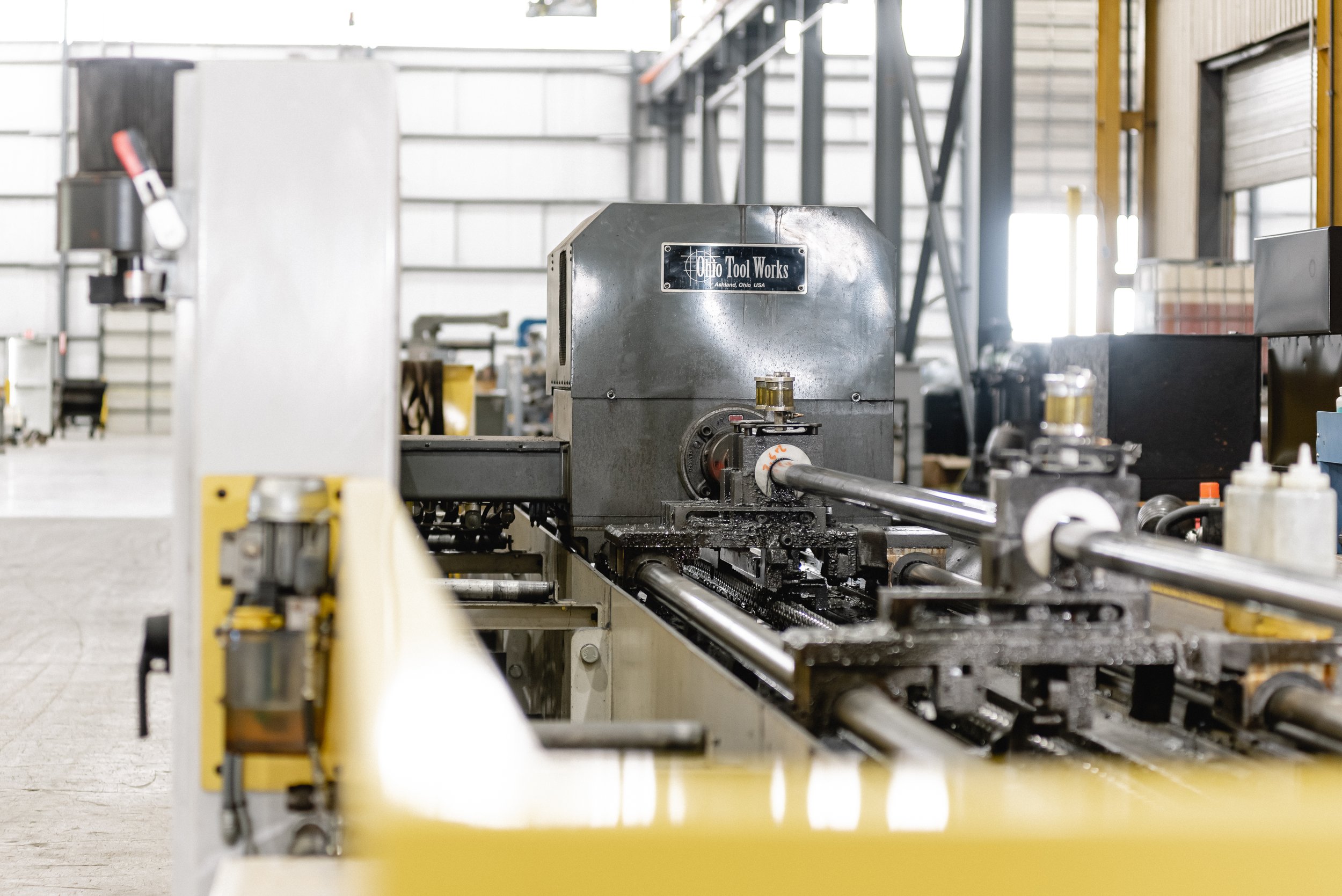

HDH Instruments is a reputable deep hole drilling service provider that meets precise machining requirements. We specialize in projects with stringent specifications, such as tight tolerance, fine surface finish, and complex geometries. Our advanced equipment and experienced team of engineers guarantee superior results that will surpass your expectations.

Deep Hole Drilling Capabilities

Ejector / Solid Drilling:

- .984” to 4.00” ID – Up to 415” Long from one end (exact length may vary by size)

- 4.00” to 8.00” ID – Up to 372” long from one end (exact length may vary by size)

Trepanning:

- 6.50” to 14.00” ID – Up to 200” Long

What is Deep Hole Drilling?

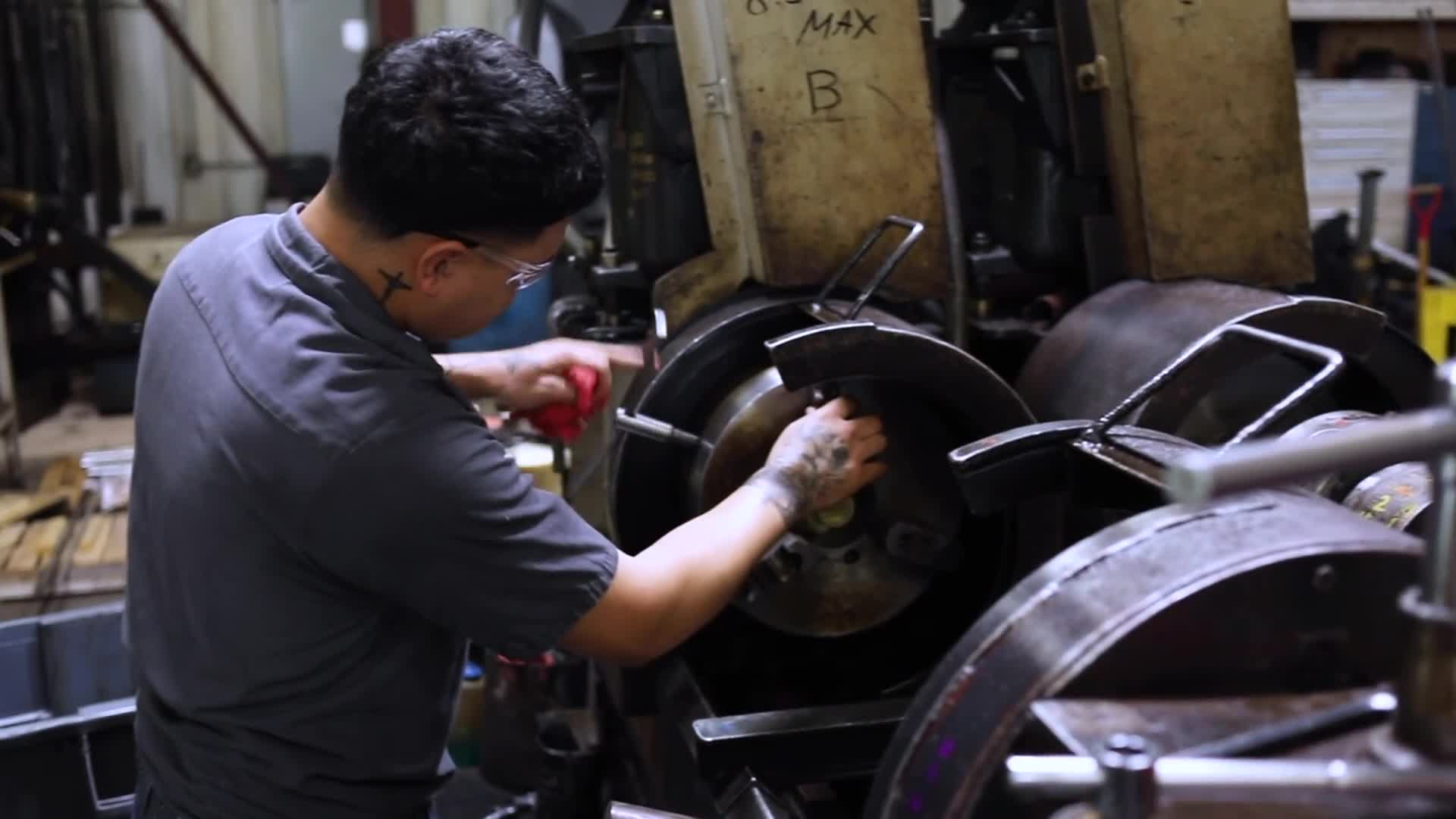

Our deep hole drilling services offer exceptional accuracy and precision compared to traditional drilling methods. The exact holes and preferred tolerances deep hole drilling machines achieve are crucial in demanding applications, such as oil & gas and aerospace components, where even the slightest deviation can lead to catastrophic failure.

Apart from standard drilling configurations, our deep hole drilling process involves specialized counter-rotational drilling setups designed to minimize runout since the drill and workpiece rotate in opposite directions, balancing the drilling forces to ensure a much more concentric hole.

Premier Deep Hole Drilling Capabilities

At HDH Instruments, we have cutting-edge drilling tools, machines, and technologies to satisfy your requirements. Depending on your specific needs, we offer off-center and on-center holes in both round and square materials. Below is an overview of our various capabilities.

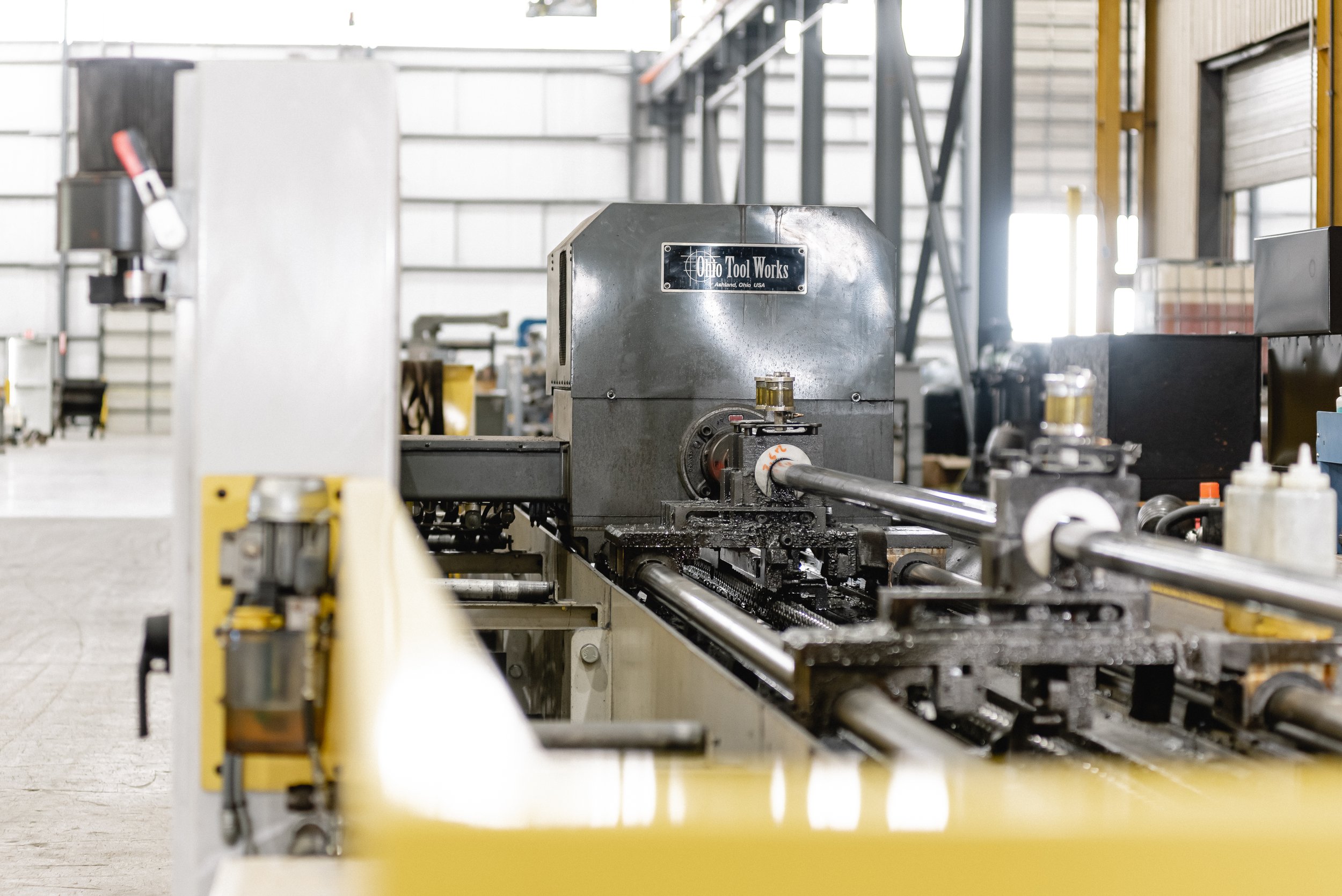

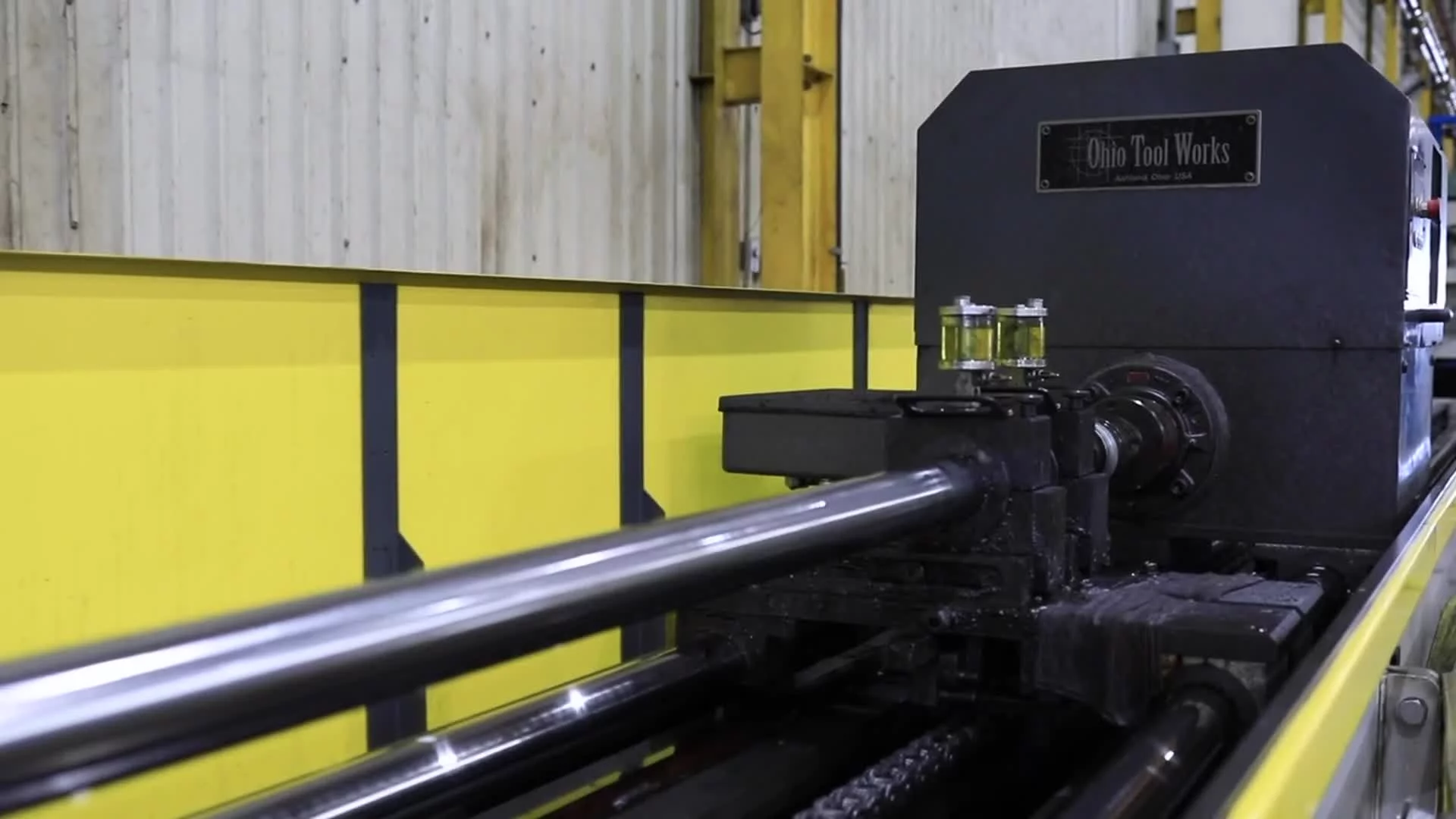

BTA Drilling

BTA drilling is an advanced method used to create deep holes in metal with high precision. It utilizes a special drilling tool attached to a long tube, making it ideal for holes with large diameters and high length to diameter ratios.

This technique stands out for its chip removal efficiency and ability to achieve higher feed rates. BTA drilling offers a cleaner, more reliable solution for complex deep-hole drilling applications.

Benefits of BTA drilling:

- Enhanced precision and accuracy

- Superior chip evacuation

- Increased drilling speeds

We offer a .984″ to 4.00″ internal diameter for up to 415″ long from one end and a 4.00″ to 8.00″ internal diameter for up to 372″ long from one end. Keep in mind the exact length may vary by size.

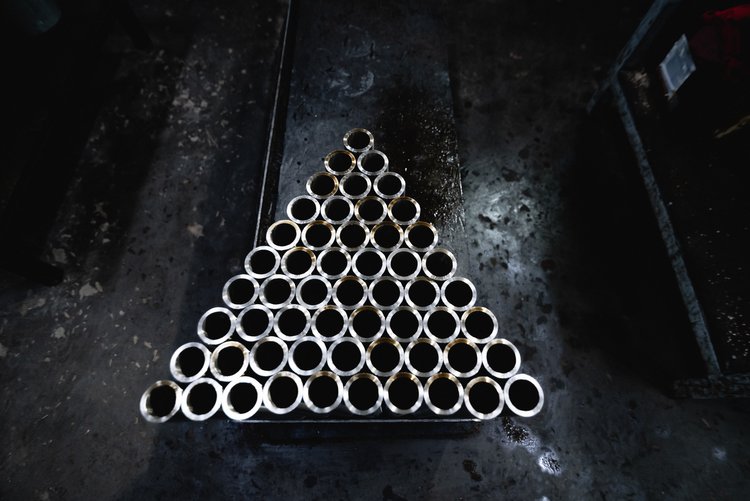

Trepanning

Trepanning is a deep hole drilling technique ideal for applications requiring larger hole diameters and in situations where a core from the raw material needs to be salvaged. It also consumes less power than conventional drilling techniques, so it’s frequently employed when machine power is limited or harder, and more difficult materials are being processed. In this process, the trepanning tool doesn’t machine the whole diameter, so it only makes a ring at the periphery.

Benefits of trepanning

- Cylinder/core removed after trepanning can be reused or recycled

- Require less energy to remove material

- Excellent for creating large holes with tight tolerances

We offer 6.50″ To 14.00″ inside diameter for parts up to 200″ long.

Applications of Deep Hole Drilling

Our deep hole drilling services are a go-to solution for our pioneer clients belonging to different industries, such as aerospace, automotive, agriculture, and defense. Here are some examples of parts and components where deep hole drilling is an essential process:

- Fuel rails for diesel engines

- Fluid assembly ends

- Aircraft landing gears

- Oilfield exploration equipment

Trust HDH Instruments for Premium Deep Hole Drilling Services

As a trusted source of deep hole drilling services, we have successfully executed numerous projects for our clients with the highest level of quality and consistency. Rest assured, we can deliver preferred tolerances to improve your project’s bottom line.

Contact us today to learn more about our range of drilling services. Call us at +12813756835, and our team will gladly assist you as we handle your next project!