HONING SERVICES

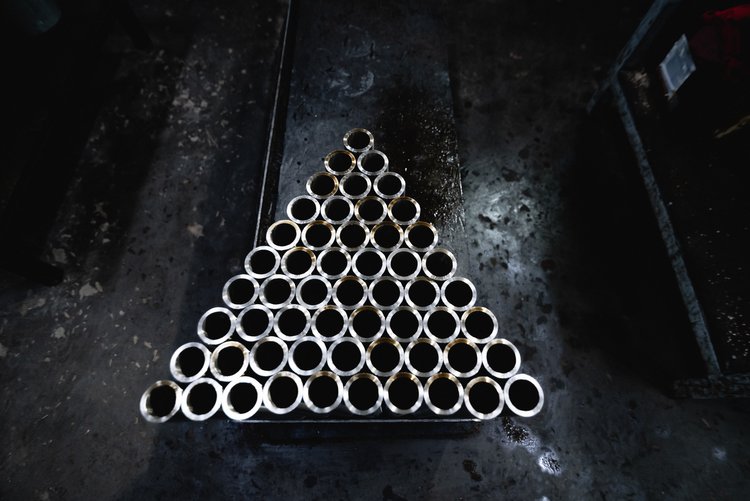

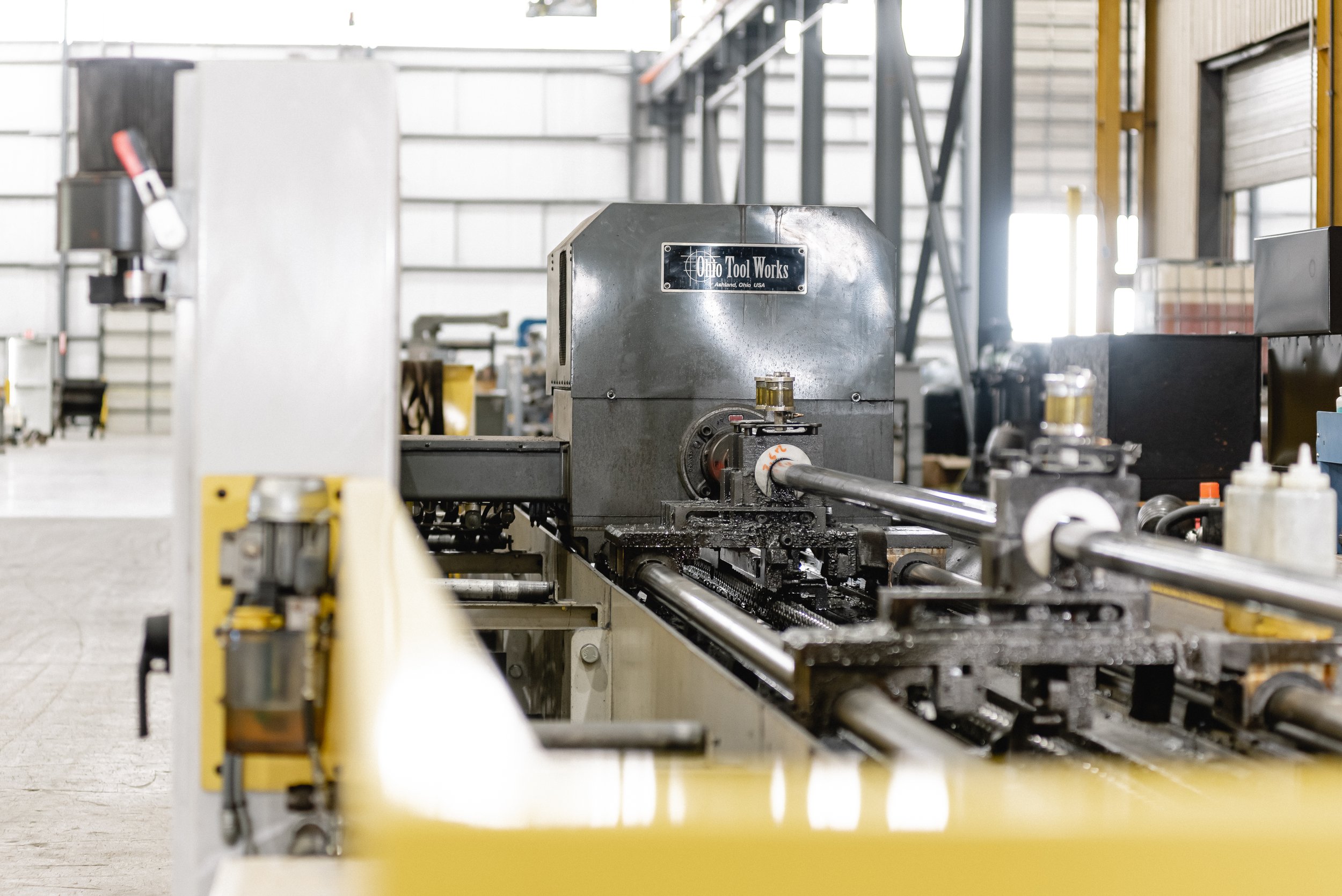

HDH Instruments can provide both vertical and horizontal honing services. We specialize in the honing of finished machined parts, fine finishes, blind end bores, and double-blind end bores.

HDH Instruments is renowned as among the top providers of honing services, ensuring high-precision outcomes that will impress our clients. The key to our success lies in our unwavering commitment to quality, advanced technology, and exceptional customer service. Therefore, we focus on implementing the latest trends in our honing services to deliver superior quality in your parts and components.

HONING SERVICES

- 0625” to .484” ID – Up to 14” Long

- .484” to 1.750” ID – Up to 360” Long

- 1.750” to 24.00” ID – Up to 600” Long

WHAT IS HONING?

Honing is a machining technique that employs an abrasive stone to slowly remove material from a metal workpiece. The stone used is usually diamond or silicon carbide, which has high hardness and can achieve a fine surface finish with minimal distortion. This procedure is predominantly used on the internal surfaces of precision parts where tight tolerances are paramount.

Our honing services are the ideal pair since honing is mainly used in conjunction with other machining processes for creating accurate and smooth finishes and accomplishing tight tolerance requirements. One primary benefit of honing is that it reduces overhead costs by eliminating the need for post-manufacturing processes, such as buffing and polishing.

BENEFITS OF OUR HONING SERVICE

Improved Accuracy

Honing allows for tighter tolerances than other machining procedures. It guarantees all parts are up to standard since the material removal rate is much slower, hence lesser heat generation.

High Compatibility

The versatility of honing means it can handle a wide range of materials like mild steel, high nickel alloys, and composites. Of course, the settings used for each material are different since they also have differing characteristics.

More Efficient

Our honing services are known for their rapid turnaround due to constant operation without breaks, so the entire project is done without delays.

Extended Tool Life

The tool life of honing machines is longer than other machining tools. The main reason is the lower pressure on the workpiece and minimal heat generated during the process, reducing wear and tear.

Typical Applications of Honing in Diverse Industries

Demanding industries with stringent regulations and specifications, such as oil and gas, aerospace, and medical, often require high-precision components to meet safety standards. Our honing services have proved to be a popular choice in these industries because they deliver consistent quality outcomes that drive success to our client’s bottom line.

Some examples of applications in varying sectors include:

- Automobile gears

- Valves

- Rollers

- Cylinders

- Fuel injectors

- Hydraulic components

- Mold cavities

- Medical implants and devices

ACHIEVE SEAMLESS QUALITY WITH OUR HONING SERVICES

At HDH Instruments, we prioritize quality and customer satisfaction in every project. Our skilled machinists are experts in honing services, ensuring high-performance results that exceed expectations. Contact us today to learn more about how our honing services can benefit your manufacturing processes. Speak to one of our experts and explore our other machining services today!